- Flexibility

- Individuality

- Security

- Internationality

Short production routes in the EU

Reliable partner for cleanroom technology since 1982

Customized solutions for your project

Menu

Close

- Clean rooms

Turnkey cleanrooms

Proven cleanroom solutions for your individual requirements & specifications.

- Air conditioning & refrigeration

Energy-saving and efficient technology for a complete cleanroom solution.

- Product protection

Tailor-made laminar flow solutions and designs with in-house production for your individual production infrastructure.

- Workstations & cleanroom furniture

With the Mini Environment from PETEK, you can rely on quick-to-install and individually designed solutions for the smallest system or production segments.

- Service

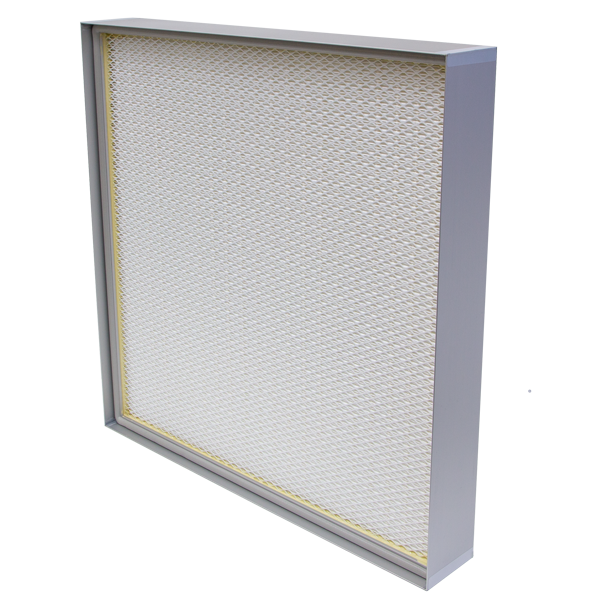

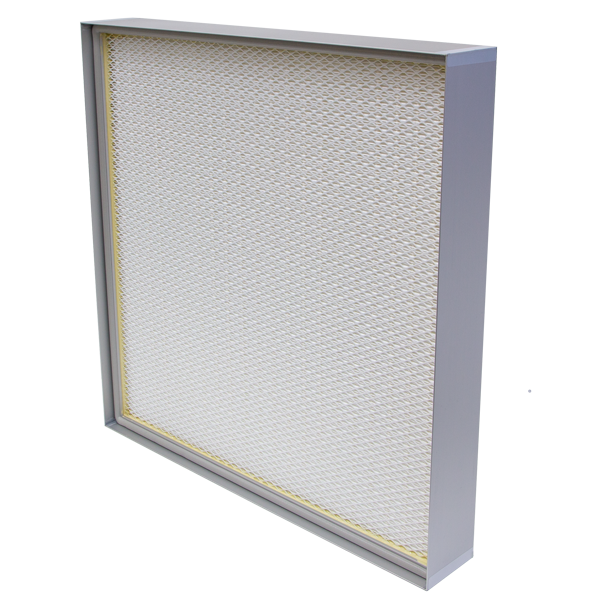

Filter

Maintenance of cleanroom classes. Factory filter scan test. Filter including test certificate

Maintenance of cleanroom classes. Factory filter scan test. Filter including test certificate - About us

A comprehensive service consisting of professional advice & proven cleanroom solutions for your individual projects.

- Clean rooms

Turnkey cleanrooms

Proven cleanroom solutions for your individual requirements & specifications.

- Air conditioning & refrigeration

Energy-saving and efficient technology for a complete cleanroom solution.

- Product protection

Tailor-made laminar flow solutions and designs with in-house production for your individual production infrastructure.

- Workstations & cleanroom furniture

With the Mini Environment from PETEK, you can rely on quick-to-install and individually designed solutions for the smallest system or production segments.

- Service

Filter

Maintenance of cleanroom classes. Factory filter scan test. Filter including test certificate

Maintenance of cleanroom classes. Factory filter scan test. Filter including test certificate - About us

A comprehensive service consisting of professional advice & proven cleanroom solutions for your individual projects.